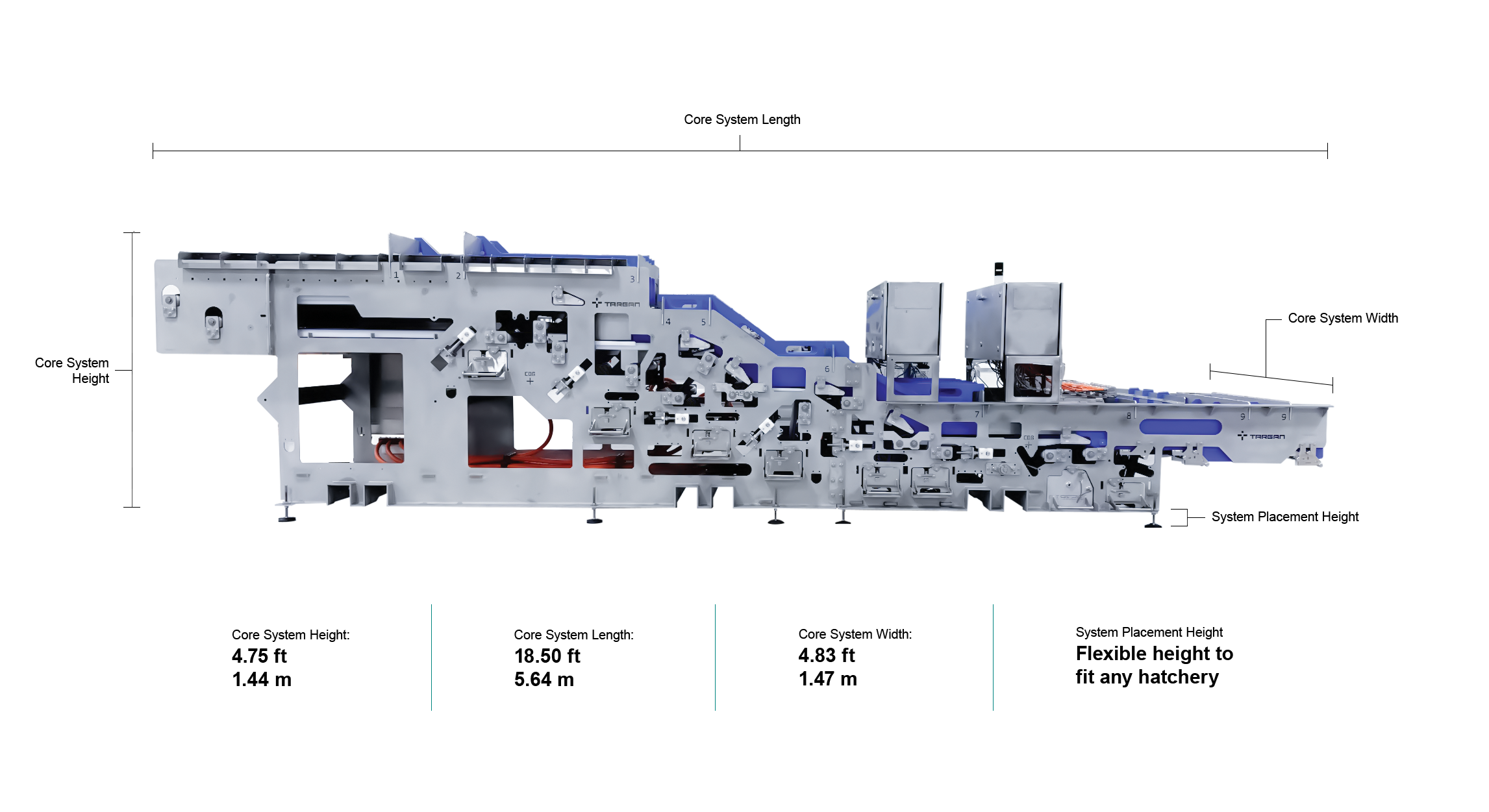

AUTOMATION

Reduces labor requirements while maintaining (or increasing) throughput potential.

MACHINE LEARNING

Consistently delivering over 97% accuracy from day one. Compatible with all feather sexable breeds.

VISION TECH

Vision systems swiftly and accurately determine chick sex, processing up to 160,000 chicks per hour, depending on configuration.

SORTING TECH

Sorting chicks with a welfare-focused, less invasive sexing process to optimize bird health

DATA CAPTURE

Enhances workflows, streamlining processes while utilizing data for performance tracking.

COMPUTING

Industrial communication systems enable efficient data processing for enhanced real-time monitoring.